Soft washing is essential for maintaining roofs and removing the damaging black streaks caused by Gloeocapsa Magma. The primary cleaning agent used in soft washing is sodium hypochlorite, which can degrade quickly due to various factors such as heat, low pH, exposure to UV light, and contamination. This degradation is a significant concern for soft wash applicators who must spray a precise percentage of sodium hypochlorite to clean different surfaces.

However, most soft wash applicators do not know their sodium hypochlorite strength or degradation level. They often over-spray chemicals, resulting in potential surface damage and harmful effects on landscaping.

Accurate sodium hypochlorite strength testing is essential, and Roof Shield offers easy, reliable, and repeatable testing that is easy to use in the field. This article will discuss the importance of testing sodium hypochlorite strength in soft washing and the need for an easy and accurate testing method.

Sodium Hypochlorite Degradation

Soft washing is the first step of the Roof Shield roof rejuvenation process, and sodium hypochlorite is the main active ingredient in soft washing. Sodium hypochlorite is an excellent cleaner used in industries worldwide. Its popularity derives from its proven, broad-spectrum action, is non-poisonous in low concentrations, and breaks down into harmless, naturally occurring products (salt, water, oxygen). The decomposition reaction is as follows:

2 NaOCl (Sodium Hypochlorite) → 2 NaCl (Sodium Chloride) + O2 (Oxygen)

Sodium hypochlorite is very reactive, which is one of the reasons it cleans so well. This reactivity also means it can degrade quickly depending on several factors. And as sodium hypochlorite in water degrades to saline, it also loses its effectiveness as a cleaner.

What Contributes to Sodium Hypochlorite Instability?

Heat is the primary factor that degrades sodium hypochlorite.

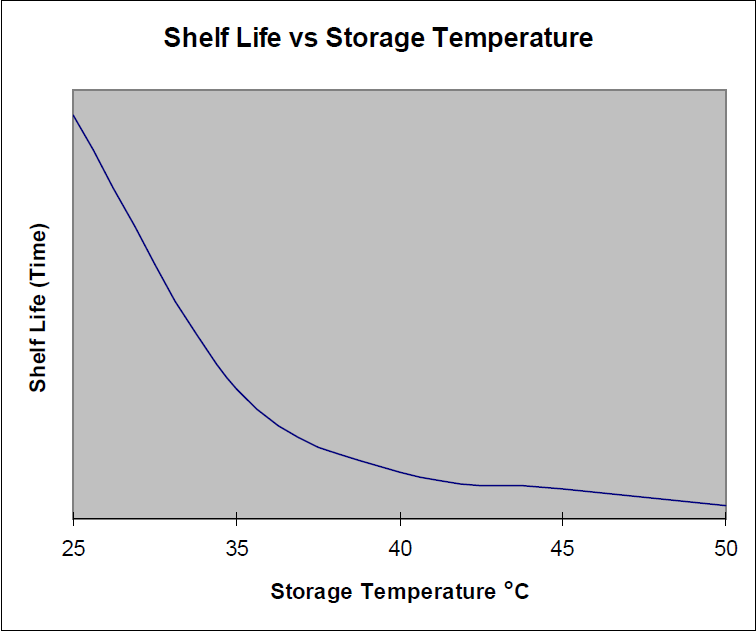

For example, the shelf life of 12.5% sodium hypochlorite decreases by approximately three times when the storage temperature is raised from 70° F to 85°F.

- 12.5% SH at 70° F lasts about three months

- 12.5% SH at 85° F lasts about a month

- 12.5% SH at 100° F lasts about a week

Sodium hypochlorite storage in vans or trailers will cause exponential degradation due to extreme temperatures. A van in 85° weather can be 135° on the inside.

- Vans get 50 degrees hotter than the outside temperature.

Trailers get 40 degrees hotter than the outside temperature

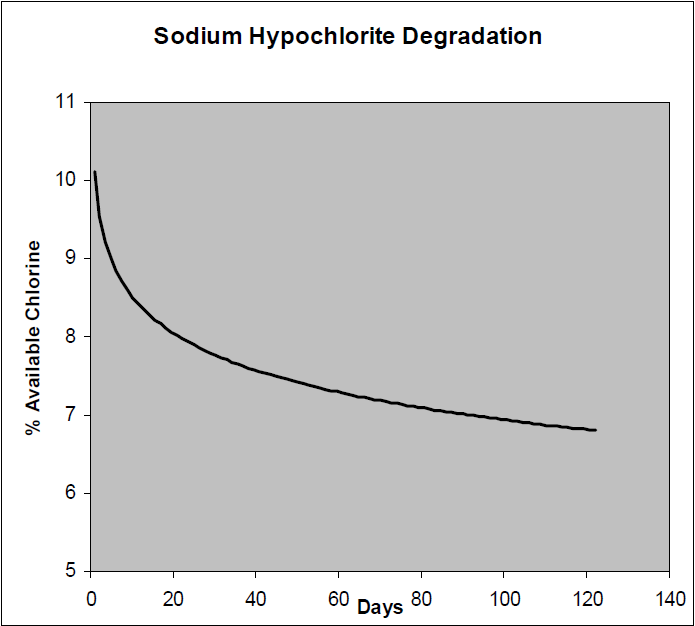

The following graphs show sodium hypochlorite degradation and how it relates to storage temperature:

Other factors that degrade sodium hypochlorite.

- Low pH – Lowering the pH will decrease the sodium hypochlorite in the solution and liberates free chlorine.

- Sunlight – Exposure to UV light degrades sodium hypochlorite.

- Contamination – Certain metals in the solution (e.g., nickel) will promote degradation.

With the degradation of sodium hypochlorite and soft wash applicators claiming to spray a precise % of sodium hypochlorite, typically 1% to 6%, to clean different surfaces from siding to roofs, it’s essential to know what the sodium hypochlorite strength is.

The problem with sodium hypochlorite testing

Most soft wash applicators do not know what percent of sodium hypochlorite they spray. They purchase sodium hypochlorite labeled with the percent that was present at manufacturing. Without the ability to test the strength of sodium hypochlorite and unaware of the actual sodium hypochlorite degradation that may have occurred, soft washers often spray a higher calculated percent than is required.

ARMA, Asphalt Roofing Manufacturers Association, recommends 3% sodium hypochlorite to clean roofs. So why do many soft washers swear they can’t clean at 3% and must use 6%? The answer is that many soft washers do not know how much their sodium hypochlorite has degraded since they purchased it. So they turn up their blend manifolds until the sodium hypochlorite ‘begins to work .’Effectively guessing at their actual application strength. And one of the significant problems with spraying with 6% is that it is much more likely to kill landscaping.

Using the standard testing method to determine sodium hypochlorite strength is not easy. Traditionally, “Sodium hypochlorite is titrated with standard thiosulfate solution to a colorless endpoint. The number of digits of thiosulfate required is proportional to the hypochlorite concentration in the original bleach sample.”

If you understand this, you must be a chemist.

A soft wash technician trying to ensure they have the right sodium hypochlorite strength should have a test that is easy, accurate, and repeatable. Roof Shield teaches all its applicators just this, a sodium hypochlorite test that is easy, accurate, repeatable, and simple to use in the field. We ensure our applicators effectively clean roofs without killing a homeowner’s landscaping. This test method is taught monthly in Roof Shield’s new applicator class and is just one of many advantages all certified Roof Shield Applicators employ.

If you would like further information on sodium hypochlorite testing, please contact us.

Darral Simmons

If you are a roofer, soft washer, or entrepreneur, Roof Shield is selling to and training applicators to service homeowners nationwide. Contact Roof Shield today to join the fast-growing roof rejuvenation and reconditioning sector.

To stay in touch with Roof Shield and always see our latest posts, like and subscribe our: